What strategies are available to reduce peak demand in a meat processing facility?

Displayed on a line chart, a load profile shows variations in power draw patterns as well as periods of peak demand. Armed with this information, you can identify the equipment and processes that are most likely causing peaks in the demand curve.

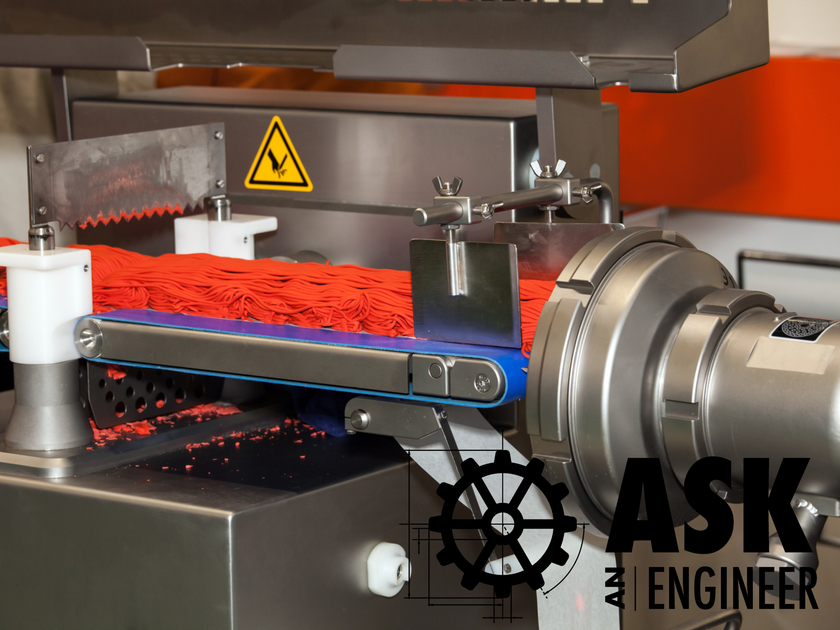

For meat processing facilities, key areas to consider include refrigeration systems, as well as motors and compressors, electric heating and lighting.

There are many effective demand-reduction strategies available. Some specific recommendations for meat processing facilities include the following:

- Use demand control or energy management systems for refrigeration equipment to monitor electric use throughout the facility and shed refrigeration load when a spike in power is detected above a set point.

- Consider variable speed drives to reduce overall motor operating load. If there is variation in the load, and the motor continues to operate at constant speed, energy is wasted. Process motors, blower fans, condenser fans, evaporator fans, pump motors, and the like, can all be candidates for variable speed drives.

- A considerable amount of energy in meat processing plants is used to pump water. Using a variety of smaller pumps instead of just a few high-horsepower units can help save energy and reduce demand.

- Compressed air is very energy intensive; use it only when absolutely necessary. If you must use compressed air, schedule it during times of lower demand.

- Use backup generators to handle large operating loads that cannot be shifted away from peak periods.

- For electric forklifts, use slow-charging battery charges that draw less power. Also, consider charging batteries during periods of reduced demand, such as nights and weekends.