Process heating equipment heats materials under controlled operations to reach desired characteristics. Examples of process heating equipment include furnaces, ovens, kilns and others. According to the U.S. Department of Energy, process heating energy consumption can typically make up 2% to 15% of the total cost of production.

Best practices for improving efficiency

Start by ensuring that process heating equipment is sized correctly for the application. Next, take steps to identify and implement operational and maintenance practices that can help improve equipment efficiency. This approach is the surest path to maximizing energy and cost savings while enabling the best use of the equipment.

Considerations for overall process heating system efficiency and use include:

- Optimizing oxygen level in flue (exhaust) gases or combustion burner air-fuel ratio

- Using flue or exhaust gas heat for combustion/process air preheating or waste heat recycling

- Scheduling furnace operations — including loading and shutdown — to avoid delays, cooling between operations, etc.

- Reducing or eliminating openings and air leakage in the furnace

- Cleaning heat transfer surfaces, such as radiant tubes, heat exchangers, tubes and heating elements

Covering your heat losses

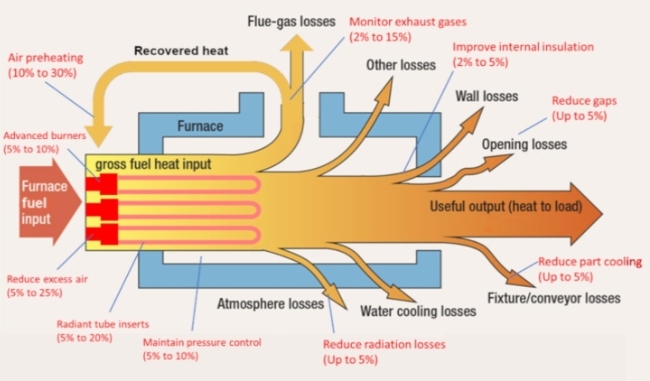

99 Heat loss can significantly affect furnace efficiency. The following diagram highlights typical heat losses and 10 energy-saving measures (and the estimated savings) to help reduce those losses.

- Advanced burners. New burners are more efficient, improving fuel combustion and reducing nitrogen oxide emissions.

- Air preheating. Reducing the heat required to raise the temperature of supply air to combustion temperature requires less fuel to do the same work.

- Monitor exhaust gases. A gas analyzer will enable you to measure the concentrations of exhaust gases and adjust burners to achieve optimal combustion.

- Improve insulation. Under normal conditions, up to 10% of heat input is lost through insulated surfaces. If furnace insulation is damaged or needs upgrading, you could be wasting a lot of energy.

- Reduce gaps. Over time, cracks and small gaps develop around burner mountings, doors and joints, resulting in leaks. Reduce heat loss by fixing broken seals and plugging holes.

- Reduce part cooling. The mass of cold parts and fixtures absorbs a lot of heat from the burners. Transfer hot parts quickly from one furnace to another and preheat them using waste heat.

- Reduce radiation losses. Hot surfaces radiate energy to any cooler surface nearby. Reduce radiation losses by adding insulation, sealing gaps and minimizing door openings.

- Maintain pressure control. Furnace pressure must be tightly controlled and well-balanced. Too much positive pressure causes hot exhaust gases to leak through doors and other openings.

- Radiant tube inserts. Spiral ceramic inserts create a nonturbulent, high convection hot gas flow that produces the highest possible rate of uniform heat transfer evenly balanced down the tube length.

- Reduce excess air. Excess air can reduce combustion efficiency and increase thermal loss. Adjust the air-to-fuel ratio to minimize the amount of excess air used for fuel combustion in burners.

By implementing these measures, you’ll save energy and money and have your furnace and process heating equipment firing on all cylinders.